Origins

Origini

CONCRETEZZA, TRADIZIONE INNOVATIVA, RECUPERO, RICERCA, ECOCOMPATIBILITÀ

Nonostante il mercato sia sempre più difficile, competitivo e spesso anche irrazionale, INCAS punta ad affermare uno spirito ed una “personalità” propria, forte, chiaramente identificabile, di riferimento sia per l’esterno (i clienti, i fornitori e le parti interessate) che per l’interno (i lavoratori, etc.).

La professionalità e la competenza insieme alla ricerca ed all’innovazione devono costituire il fondamento per sostenere questo approccio al lavoro. Tutti coloro che operano all’interno e per conto della Conceria sono quindi chiamati a condividere tale spirito e collaborare con la Direzione per:

- assicurare un’attenta gestione e monitoraggio di ogni fase di realizzazione del prodotto, affinché il manufatto fi nale possieda gli elevati standard qualitativi definiti dalla Conceria, i requisiti attesi dal cliente e quelli cogenti applicabili

- garantire il puntuale rispetto dei tempi di consegna concordati e delle prestazioni di prodotto dichiarate

- interpretare le esigenze del consumatore finale, operando con la massima flessibilità per il soddisfacimento di richieste personalizzate e particolari

- assicurare trasparenza e chiarezza nella comunicazione con i clienti e con la generalità più vasta del pubblico, comprese le Autorità e gli Enti di controllo, in particolare per quanto riguarda gli aspetti ambientali associati alle attività, prodotti e servizi della Conceria, mediante una Dichiarazione Ambientale aggiornata annualmente

- attenersi a principi di trasparenza, correttezza e buona fede nei rapporti con istituzioni, clienti, fornitori, concorrenti evitando atti sleali che violino il

Codice di Condotta e Responsabilità Sociale sottoscritto

- assicurare il pieno rispetto di tutti i requisiti cogenti, normativi e regolamentari applicabili in materia ambientale, sociale e di salute e sicurezza dei lavoratori

(compreso il Contratto Collettivo Nazionale di Lavoro del settore conciario)

- valutare gli aspetti ambientali e di qualità connessi ad ogni nuova attività, prodotto o processo della Conceria

Company Policy

Company Policy

PRAGMATISM, INNOVATIVE TRADITION, RECYCLING, ECO-FRIENDLY APPROACH.

Expertise and competence, along with research and innovation, are the foundations of this approach towards work. All those who work within and for INCAS are encouraged to share such attitude with the Management and collaborate to:

- Ensure accurate management and monitoring of each step of the process so that the final good has the high-quality standards established by the Tannery, as well as the characteristics expected by the client and the relevant, compelling requirements

- Ensure punctual compliance with the agreed delivery times and with the declared product performances

- Understand the final customer’s needs, working with the finest adaptability to fulfill personalized and specific demands

- Ensure transparency and clarity within the communication both with our clients and the rest of the community, including authorities and controlling bodies, especially concerning the environmental aspects linked to the activities, the products, and the services of our Tannery, through an Environmental Statement updated every year

- Comply with values such as transparency, loyalty, and good faith while doing business with institutions, clients, suppliers, and competitors, avoiding dishonest actions that would violate the subscribed Code of Conduct and Social Responsibility

- Ensure the full compliance with the compelling requirements, laws, and regulations, applicable in terms of environment, society, and workers’ health and safety (including the National Collective Labour Agreement of the tanning sector)

- Assess the environmental and quality aspects linked to each new activity, product, or process of our Tannery

Values

INiziative Conciarie ASsociate embodies our relentless pursuit of excellence and our passion for preserving the essence of our leather.

Production organization

Careful work procedures, cutting-edge technologies, attention to the skills of our staff, and our goal-oriented working approach are the key elements of our organization. An articulated system of operating procedures and work instructions leads the activities of our various departments under the direct and continuous control of a team of managers who are aware of the quality level of our products and the importance of guaranteeing their consistency over time. For over ten years, our tannery has been operating with ISO 9001 certification issued by I.CE.C. (Accredited Body by Accredia).

Attention to the customer

A modern organization of customer service staff allows INCAS to professionally and rapidly manage its customer relationships and ensure a personalized service. Today, the Commercial Department counts eight employees dedicated to specific markets or notable clients. INCAS provides continuous assistance and support in all phases of the relationship: prototyping, sampling, and monitoring the deliveries. Attention to the customer means the ability to interpret and fulfill any request.

Research and development of new products

The entire process from research to prototype development to the following industrialization phase is controlled by precise operating procedures and computer tools that give the added value distinguishing INCAS from its competitors. The Testing Laboratory operates in support of the Research Department by carrying out the necessary technical checks to assure the customer of the required performance of materials.

Quality control

High-quality leather production is guaranteed by a system of checks and selections spread throughout the production cycle and carried out by qualified staff with deep knowledge of our ‘leather product’. All quality controls and chemical-physical analyses are recorded and documented. All lots of leather leaving our company are 100% controlled and registered at all stages of the production and selection. No leather is shipped until the Incas Control Plan is proven to be completed and respected.

Numbers

Numbers

Founded in

1972

Employees

over 150

Production Capacity

1.500.000 Mq

Total square meters of our plants

22.000

Export Countries

30 – 40

Registered trademarks

3

Certified product lines

2

Certified Processes

1

ESG (Environmental, Social, Governance) certifications

10

Iniziative Conciarie ASsociate

INiziative Conciarie ASsociate

Is a “container” of ideas, research, evolution, and design, whenever excellence is necessary to produce highly valued leather. INiziative Conciarie ASsociate; three divisions designed to perform a working style marked by luxury and ongoing research.

Warehouses

Warehouses

Our warehouses, located in strategic positions of the production process (raw hides, wet blue/crust, pre-finishing, and finished), enable us to respond to any of our customers’ requests promptly and to manage our orders faster.

Analytical laboratory

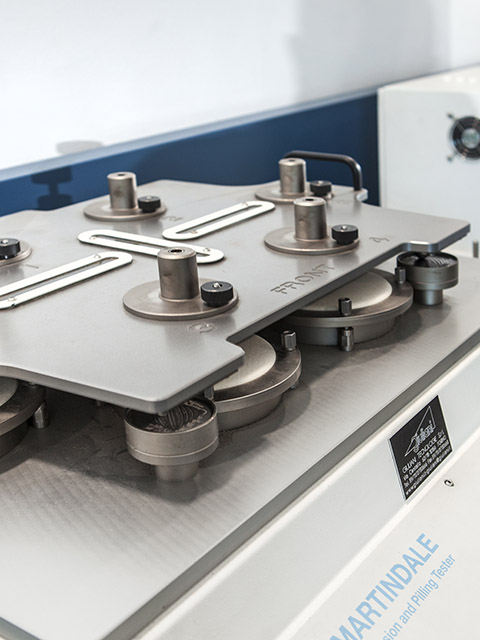

Our analytical laboratory

Our in-house analytical laboratory performs physical tests and controls on incoming chemicals to ensure quality and consistency during production.

Its equipment includes:

– Flexometer

– Veslic (for rubbing tests)

– Feeler gauge

– Dynamometer (tool for measuring tear strength and tensile strength and finish adhesion)

– Martindale Abrasimeter (for measuring abrasion resistance)

– Lastometer (for measuring grain distension and tensile strength)

– Sunotest (for measuring colour fastness to artificial light)

– Climatic Chamber (for accelerated aging tests using heat and humidity)

– Spray Test (for testing resistance to surface wetting)

– IR Spectrophotometer (Spectrum One Perkin Elmer)

– UV/VIS Spectrophotometer (Lambda 35 Perkin Elmer)

– pH-Meter (Mettler Toledo)

Raw hides

Raw hides

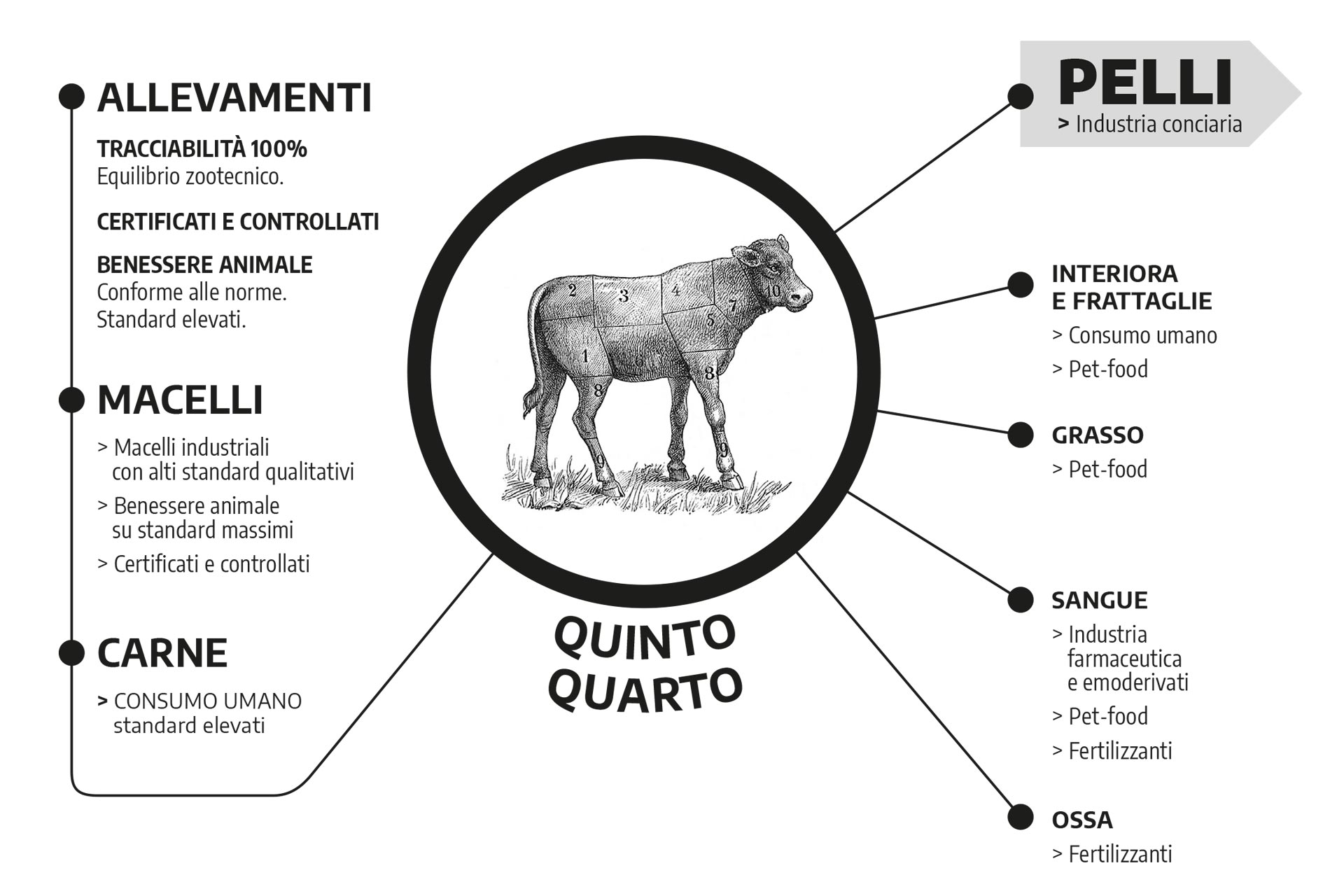

FROM WASTE TO RESOURCE. INiziative Conciarie ASsociate production process transforms raw hides, a by-product of the zootechnical industry, using them in its tanning producing process. Global pollution is thus reduced, preventing hides from becoming waste and being treated as “special waste”.

Raw hides

TRACEABILITY CONTROL

QUALITY CONTROL

SELECTION OF HOMOGENEOUS LOTS

VANTAGGI

REDUCTION OF PROCESSING WASTE

LESS WASTE =

LESS WASTE SENT TO THE LANDFILL

Divisions

Product divisions

Tre divisioni di prodotto INiziative Conciarie ASsociate per coprire la richiesta di pellami di alta qualità per le varie destinazioni d’uso.

EXCLUSIVE NATURAL LEATHER

INCAS is renowned worldwide thanks to its vegetable tanning process characterized by unique technical and qualitative features that are also environmentally friendly.

Our vegetable leather is most commonly used to produce footwear and leather goods, thanks to a highly varied product catalogue and the opportunity to develop customized articles upon specific customer requests.

LEATHER GARMENTS & HAIR-ON BABY CALF

ITALTAN division specializes in the production of leather for garments and calf leather with hair. ITALTAN range of high-quality leather meets the different manufacturing needs for footwear, leather goods, and garments.

The high technology employed by our R&D laboratories has enabled us to develop leather of extreme softness and brightness.

Baby calves, half calves, buffaloes, kangaroos, and lambs are the foundations on which Italtan has built its position as a reference for the major world brands.

HIGH QUALITY TRADITIONAL LEATHER

Il Veliero processes and produces a high-protein line characterized by a reduced release of amines from chrome-tanned side calves. Il Veliero line is certified by ICEC as “100% Italian leather,” starting its production process from (wet salted) rawhides.

Our leather is fuller, rounder, rubberier, more elastic, and with superior fine grain. Our “High-protein Line” employs considerable resting time for skins in Wet blue (90 days) in very rigorous storage conditions so that it can fully complete the olation process on the skins.

Production process

Sustainability

Production process

Our entire supply chain is 100% MADE IN ITALY

Riviera

SOAKING

Homogeneous lots allow a precise soaking along with reduced processing times

LIME

Bath recycling

ADVANTAGES

MORE FLEXIBLE AND SOFTER LEATHER

because of the amines staying in the skins thanks to our particular system of bath recycling

-53,7%

WATER CONSUMPTION IN THE LIMING PROCESS DUE TO THE RECYCLING OF THE BATH unique system of recycling of the bath

-32,5%

SODIUM SULPHIDE

PROCESS CONTROLLED BY “HÜNI TECHNOLOGY”

Organic tanning

ORGANIC TANNING EN 15987 LEGISLATION

LEATHER 40075

Use of vegetal tanning coming from FSC certified wood

ADVANTAGES

High-quality leather realized through natural tanning process certified in all its stages

0,032%=

320PPM

VERAGE VALUES OBSERVED HEAVY METALS CONTENT lower than the standards established by UNI EN ISO 17072-2 (± 0,1)

PROCESS CONTROLLED BY “HÜNI TECHNOLOGY”

LOW-IMPACT CHROME

SLOW LEATHER

OLATION PROCESS

Skin aging in a controlled environment for at least 90 days

ADVANTAGES

Better quality and cutting yield

-13%

RETANNAGE PRODUCTS

-18%

CHROME IN WASTEWATER

PROCESS CONTROLLED BY “HÜNI TECHNOLOGY”

Retanning

USE OF LIQUID CHEMICAL PRODUCTS RATHER THAN POWDERED ONES

ADVANTAGES

LESS CHEMICAL PRODUCTS USED

-8%

CHEMICAL PRODUCTS SENT TO PLANT EFFLUENT

PROCESS CONTROLLED BY “HÜNI TECHNOLOGY”

Finishing

LATEST GENERATION MACHINERY

LOWER ENVIRONMENTAL IMPACT

MORE SAFETY

ADVANTAGES

NO PRODUCTS CONTAINING FLUORINATED, XYLENE, TETRACHLOROETHYLENE

<

LESS “VOC” EMISSIONS INTO THE ATMOSPHERE

-14%

LESS CONSUMPTION OF FINISHING PRODUCTS

Environmental

protection

100% RENEWABLE ELECTRICITY

EFFLUENT PRE-TREATING PLANT

The internal plant enables to intervene in case of emergency directly.

ADVANTAGES

62,4%

DROP IN “COD” EMISSIONS FROM THE EFFLUENT PRE-TREATING PLANT (2018) CONSIDERABLY LOWER THAN THE DISTRICT AREA’S AVERAGE

–

LESS WASTE SENT TO THE LANDFILL

Italiano

Italiano